YNDKIN系列低压变频器

1.1变频器的命名规则1.2 YND800系列变频器机型列表变频器型号输入电压/V额定输出功率/KW额定输入电流/A额定输出电流/A适配电机/KW制动单元YND800-0R7G-2SB单相220~2400.758.24.50.75标准内置 YND8

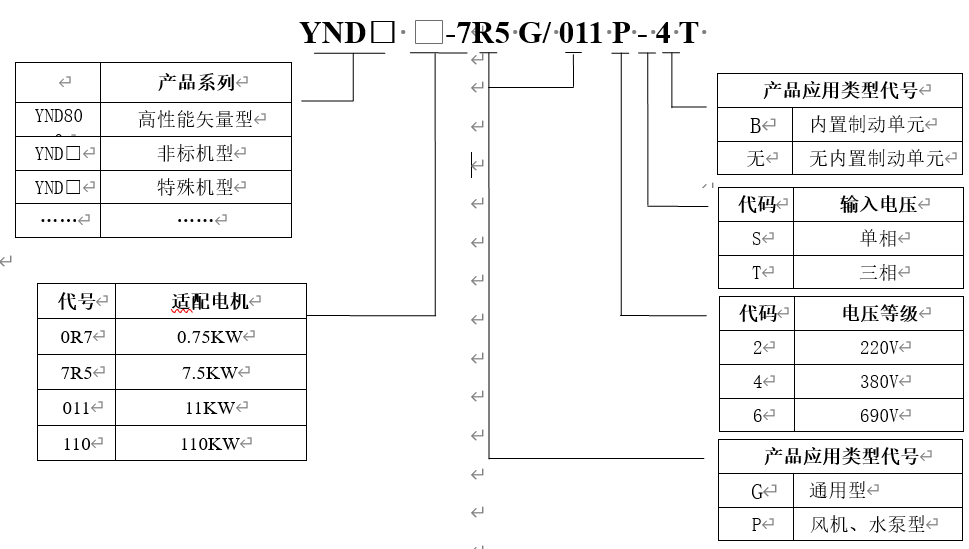

1.1变频器的命名规则

1.2 YND800系列变频器机型列表

变频器型号 | 输入 电压/V | 额定输出 功率/KW | 额定输入电流/A | 额定输出电流/A | 适配电机 /KW | 制动单元 |

YND800-0R7G-2SB | 单相 220~240 | 0.75 | 8.2 | 4.5 | 0.75 | 标准内置 |

YND800-1R5G-2SB | 1.5 | 14.2 | 7.0 | 1.5 | ||

YND800-2R2G-2SB | 2.2 | 23.0 | 10 | 2.2 | ||

YND800-0R7G-2TB | 三相 220~240 | 0.75 | 5.0 | 4.5 | 0.75 | |

YND800-1R5G-2TB | 1.5 | 7.7 | 7.0 | 1.5 | ||

YND800-2R2G-2TB | 2.2 | 11 | 10 | 2.2 | ||

YND800-0R7G-4TB | 三相 380~480 | 0.75 | 3.4 | 2.5 | 0.75 | |

YND800-1R5G-4TB | 1.5 | 5.0 | 3.7 | 1.5 | ||

YND800-2R2G-4TB | 2.2 | 5.8 | 5 | 2.2 | ||

YND800-004G/5R5P-4TB | 4.0/5.5 | 10/15 | 9/13 | 4.0/5.5 | ||

YND800-5R5G/7R5P-4TB | 5.5/7.5 | 15/20 | 13/17 | 5.5/7.5 | ||

YND800-7R5G/011P-4TB | 7.5/11.0 | 20/26 | 17/25 | 7.5/11.0 | ||

YND800-011G/015P-4TB | 11.0/15.0 | 26/35 | 25/32 | 11.0/15.0 | ||

YND800-015G/018P-4TB | 15.0/18.5 | 35/38 | 32/37 | 15.0/18.5 | ||

YND800-018G/022P-4TB | 18.5/22.0 | 38/46 | 37/45 | 18.5/22.0 | ||

YND800-022G/030P-4TB | 22.0/30.0 | 46/62 | 45/60 | 22.0/30.0 | ||

YND800-030G/037P-4TB | 30.0/37.0 | 62/76 | 60/75 | 30.0/37.0 | ||

YND800-037G/045P-4TB | 37.0/45.0 | 76/90 | 75/90 | 37.0/45.0 | ||

YND800-045G/055P-4T | 45.0/55.0 | 90/105 | 90/110 | 45.0/55.0 |

可选内置 | |

YND800-055G/075P-4T | 55.0/75.0 | 105/140 | 110/150 | 55.0/75.0 | ||

YND800-075G/090P-4T | 75.0/90.0 | 140/160 | 150/176 | 75.0/90.0 | ||

YND800-090G/110P-4T | 90.0/110.0 | 160/210 | 176/210 | 90.0/110.0 | 外置 | |

YND800-110G/132P-4T | 110.0/132.0 | 210/240 | 210/250 | 110.0/132.0 | ||

YND800-132G/160P-4T | 132.0/160.0 | 240/290 | 250/300 | 132.0/160.0 | ||

YND800-160G/185P-4T | 160.0/185.0 | 290/330 | 300/340 | 160.0/185.0 | ||

YND800-185G/200P-4T | 185.0/200.0 | 330/370 | 340/380 | 185.0/200.0 | ||

YND800-200G/220P-4T | 200.0/220.0 | 370/410 | 380/415 | 200.0/220.0 | ||

YND800-220G/255P-4T | 220.0/255.0 | 410/460 | 415/470 | 220.0/255.0 | ||

YND800-255G/280P-4T | 255.0/280.0 | 460/500 | 470/520 | 255.0/280.0 | ||

YND800-280G/315P-4T | 280.0/315.0 | 500/580 | 520/600 | 280.0/315.0 | ||

YND800-315G/355P-4T | 315.0/355.0 | 580/650 | 600/640 | 315.0/355.0 | ||

YND800-355G-4T | 355.0 | 650 | 640 | 355.0 | ||

YND800-400G-4T | 400.0 | 740 | 730 | 400.0 | ||

YND800-450G-4T | 450.0 | 850 | 840 | 450.0 | ||

YND800-500G-4T | 500.0 | 900 | 880 | 500.0 |

1.3 690V YND800系列变频器机型列表

变频器型号 | 输入 电压/V | 额定输出 功率/KW | 额定输入电流/A | 额定输出电流/A | 适配电机 /KW |

YND800-022G-6T | 三相 690V | 22.0 | 35 | 27 | 22.0 |

YND800-030G-6T | 30.0 | 40 | 35 | 30.0 | |

YND800-037G-6T | 37.0 | 47 | 45 | 37.0 | |

YND800-045G-6T | 45.0 | 52 | 54 | 45.0 | |

YND800-055G-6T | 55.0 | 65 | 62 | 55.0 | |

YND800-075G-6T | 75.0 | 85 | 86 | 75.0 | |

YND800-090G-6T | 90.0 | 95 | 95 | 90.0 | |

YND800-110G-6T | 110.0 | 118 | 131 | 110.0 | |

YND800-132G-6T | 132.0 | 145 | 147 | 132.0 | |

YND800-160G-6T | 160.0 | 165 | 163 | 160.0 | |

YND800-185G-6T | 185.0 | 190 | 198 | 185.0 | |

YND800-200G-6T | 200.0 | 210 | 216 | 200.0 | |

YND800-220G-6T | 220.0 | 230 | 240 | 220.0 | |

YND800-255G-6T | 255.0 | 255 | 274 | 255.0 | |

YND800-280G-6T | 280.0 | 286 | 300 | 280.0 | |

YND800-315G-6T | 315.0 | 334 | 328 | 315.0 | |

YND800-355G-6T | 355.0 | 360 | 380 | 355.0 | |

YND800-400G-6T | 400.0 | 411 | 426 | 400.0 | |

YND800-450G-6T | 450.0 | 460 | 466 | 450.0 | |

YND800-500G-6T | 500.0 | 518 | 540 | 500.0 | |

YND800-560G-6T | 560.0 | 578 | 600 | 560.0 | |

YND800-630G-6T | 630.0 | 655 | 680 | 630.0 | |

YND800-710G-6T | 710.0 | 730 | 765 | 710.0 | |

YND800-800G-6T | 800.0 | 825 | 870 | 800.0 | |

YND800-1000G-6T | 1000.0 | 1180 | 1010 | 1000.0 |

项目 | 规格 | |

功率 输入 | 额定电压 | 3相:380V~480V(或者:690V);电压持续波动±10% ,短暂波动-15%~+10% ,即323V~528V(或者:587~760V); 电压失衡率<3%,畸变率满足IEC61800-2要求 |

额定输入电流 | 参见表2-1 | |

额定频率 | 50Hz/60Hz,波动范围±5% | |

功率 输出 | 标准适用电机 | 参见表2-1 |

额定容量 | 参见表2-1 | |

额定电流 | 参见表2-1 | |

输出电压 | 额定输入条件下输出3 相,0~额定输入电压,误差小于±3% | |

基本功能 | 最高频率 | |

载波频率 | 1.0kHz~16.0kHz ,可自动调整载波频率 | |

输入频率分辨率 | 数字设定:0.01Hz;模拟设定:0.1Hz | |

控制方式 | 无PG矢量控制、无PG矢量控制1、V/F控制、转矩控制、有PG矢量控制。 | |

启动转矩 | 0.5Hz/150% | |

过载能力 | G型机:150%额定电流60秒钟;180%额定电流10秒钟 P型机:120%额定电流60秒钟;150%额定电流10秒钟 | |

转矩提升 | 自动转矩提升;手动转矩提升0.1%~30.0% | |

加减速曲线 | 直线或S曲线加减速方式。四种加减速时间,范围0.0~3600.0s | |

直流制动 | 直流制动频率:0.00Hz~最大频率,制动时间:0.0s~50.0s,制动动作电流值:0.0%~100.0% | |

点动控制 | 点动频率范围:0.00Hz~50.00Hz。点动加减速时间0.0s~3600.0s | |

简易PLC 、多段速运行 | 通过内置PLC 或控制端子实现最多16段速运行 | |

内置PID | 可方便实现过程控制闭环控制系统 | |

自动电压调整(AVR) | 当电网电压变化时,能自动保持输出电压恒定 | |

电流抑制 | VF运行负载变化时,自动限制输出电流大小,防止过流跳闸,实现“挖土机”特性 | |

快速限流功能 | 最大限度减小过流故障,保护变频器正常运行 | |

动态过压抑制 | 运行频率变化时自动抑制能量回馈大小,防止母线过压跳闸 | |

振荡抑制 | 优化VF振荡抑制算法,实现VF稳定运行 | |